4L/H mini spray dryer

YC-018 mini spray dryer is self contained and supplied complete and ready for immediate operation. All major components are housed within a stainless steel cabinet and the unit can be used on a bench top or with an optional stainless steel stand. The system was designed to be stand by a keyboard, conducted by a colorful crystal screen of touch guidance mode , and allowed two modes of run: Automatic-mode, and Eye-monitored mode for the purpose of easily controlling experimental process .

YC-018 MINI SPRAY APPLICATIONS

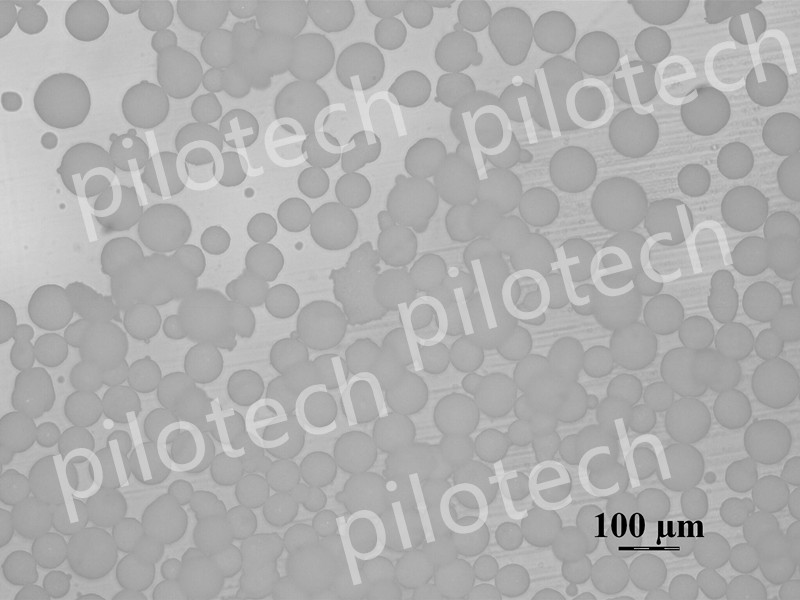

YC-018 mini spray dryer can be used in a wide range of applications where the production of a free-flowing powder sample(10-120μm) is required. This technique has successfully processed materials in the following areas:

Beverages • Flavours and Colourings • Milk and Egg Products • Plant and Vegetable Extracts • Pharmaceuticals • Heat Sensitive Materials • Plastics • Polymers and Resins • Perfumes • Ceramics and Advanced Materials •

Soaps and Detergents • Blood • Dyestuffs • Foodstuffs • Adhesives • Oxides • Textiles • Bones, Teeth and Tooth Amalgam and many others. Most solutions and suspensions can be spray dried providing that the resulting product has the characteristics of a solid material.

YC-018 MINI SPRAY DRYER TECHNIQUE

l A menu driven microprocessor controller allows the selection of inlet temperature, airflow, automatic de-blocker frequency and pump speed. The controller features an USB output for connection to a PC or datalogger and software allows the control and monitoring of all functions and printing of results(optional).

l The self-priming peristaltic pump delivers the sample liquid from a container through a small diameter jet into the main chamber. At the same time an integral compressor pumps air into the outer tube of the jet which causes the liquid to emerge as a fine atomised spray into the drying chamber.

l Heated air is blown through the main chamber evaporating the liquid content of the atomised spray. The solid particles of the material, which are normally in a free flowing state, are then separated from the exhaust air flow by a cyclone and collected in the sample collection bottle. The exhaust airflow is directed through a flexible 60 mm diameter hose direct to atmosphere or to an existing extraction system.

YC-018 MINI SPRAY DRYER ADVANTAGES

l Two modes of run: Automatic-mode, and Eye-monitored mode for the purpose of easily controlling experimental process . PLC controller, LCD touch panel control fascia with flow path of system.

l air oilless compressor , the sound is low than 60db

l Made of SUS-316 Stainless steel. Easy operating.

l To assure accurate temperature control and easy parameter adjusting, YC-015 applies PID.

l The self-priming peristaltic pump delivers the sample liquid from a container through a small diameter jet into the main chamber to avoid secondary pollution.. To make sure the process conducted steady and smoothly, magnetic agitator is optional to make the solution well mixed.

l Narrow size distribution of particles.(10-100um)

l Automatic de-blocking device prevents the nozzle from becoming blocked and variably controlled

YC-018 MINI SPRAY DRYER TECHNIACL INFORMATION

Sr.no Parameter Pilotech YC-018 Spray Dryer 1 Power 5500W 2 Voltage 220V,50/60 Hz 3 Atomizer material SUS 316 Stainless steel 4 Evaporating Capacity 4 l/h for water 5 Airflow 0-330 mᶟ/h 6 max. Input temperature 350⁰C 7 Heater power 5000W 8 Temperature precision ±1⁰C 9 Spray gas 4.2mᶟ/h, 2-5bar 10 Nozzle jet 0.7mm standard/(0.5/0.75/1.0/1.5/2.0mm available) 11 Nozzle type Two fluid nozzle 12 Possible particle size range 5-100µm 13 Mean Residence time 1.0-1.5 sec 14 Operation mode Automatic/Manual 15 Max. Sample feed 5000ml/hr 16 Minimum sample volume 100ml 17 Spray chamber material SUS 304 stainless steel 18 Cyclone separator material SUS 304 stainless steel 19 Receiving tank material SUS 304 stainless steel 20 Body material SUS304 Stainless steel 21 Seal of cyclone/cylinder Silicone 22 Deblocking Automatic 23 Sound <60db 24 Dimensions 950*750*1700 25 Weight 150KG 26 Display 7-Inch LCD display for Heat, Spray, Pump, Air pressure, de-blocker frequency 27 Thermal protection Blower does not stop until temp <90⁰C 29 Inert loop (for organic solvents) Optional